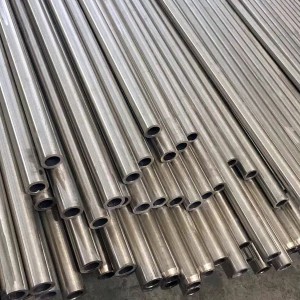

I-Waspaloy - Ingxube Ehlala Njalo Yezicelo Zokushisa Okuphezulu

| Ingxubevange | isici | C | Si | Mn | S | P | Mo | Cr | Al | Ti | Fe | Cu | B | Zr |

| I-Waspaloy | Ubuncane | 0.02 | 3.5 | 18.0 | 1.2 | 2.75 | 0.003 | 0.02 | ||||||

| Ubuningi | 0.10 | 0.75 | 1.0 | 0.03 | 0.03 | 5.0 | 21.0 | 1.6 | 3.25 | 2.0 | 0.5 | 0.01 | 0.12 | |

| okunye | I-Co:12.0~15.0,Ni:ibhalansi | |||||||||||||

| Isimo se-Aolly | Amandla okudonsa I-RmUbuncane I-Mpa | Amandla okukhiqiza I-RP 0.2I-Min Mpa | Ukwelulwa A 5Ubuncane% | Ukunciphisa Yendawo,ubuncane, % | Ubulukhuni bukaBrinell HB |

| isixazululo+ ukuzinza + ukuqina kwemvula | 1100 | 760 | 15 | 18 | 310 |

| Ubuningig/cm3 | Indawo Yokuncibilika℃ |

| 8.19 | 1330~1360 |

Induku, Ibha, Ucingo kanye Nesitoko Sokwakha- I-ASTM B 637, ISO 9723, ISO 9724, ISO 9725, SAE AMS 5704, SAE AMS 5706,

Ipuleti, Ishidi kanye Nokuhlubula -I-SAE AMS 5544

Bhala umlayezo wakho lapha bese uwuthumela kithi